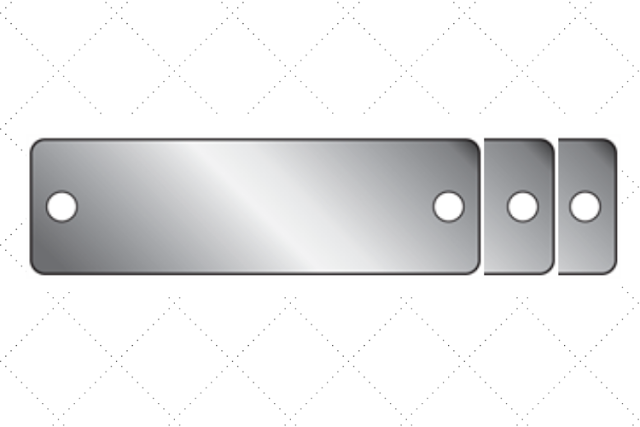

Anodized Aluminium Nameplates

An aluminum nameplate anodized implies designs are screen printed and fixed underneath the anodic layer for additional solidness. The aluminum is synthetically treated to open the pores of the metal, at which time an anodyne color is imprinted on the metal. This color really infiltrates the surface of the metal and is then fixed into the aluminum in a concoction shower. This helps the name plate manufacturer to deliver an extremely climate safe plate that will give numerous long stretches of administration in open air conditions.

ALUMINIUM NAMEPLATE

Aluminum name plate manufacturer generally uses the anodized method to give excellent protection from consumption, synthetic compounds, and solvents. Anodized aluminum nameplates are a savvy option in contrast to the Metal photo.

Anodization Process

An aluminum anodized expands erosion opposition. The procedure is classified "anodizing" in light of the fact that the part to be dealt with structures the anode terminal of an electrical circuit. Anodizing expands erosion opposition and wear obstruction, and gives better attachment to painting preliminaries and pastes than bare metal. Anodic metals can likewise be utilized for various restorative impacts, either with thick permeable coatings that can assimilate colors or with thin straightforward coatings that add obstruction impacts to reflected light.

BHARAT METAL PROCESS-ALUMINIUM NAMEPLATE

Aluminum nameplate manufacturer follows anodization process which changes the precious stone structure of the metal close to the required needed shape. Thick coatings are ordinarily permeable, so a fixing procedure is regularly expected to accomplish erosion opposition. Anodized aluminum surfaces, for instance, are harder than normal aluminum. However, the anodized process can be enhanced with expanding thickness or by applying appropriate fixing substances.

Comments

Post a Comment